Project X

Next level technology for ultimate response

Glide. Flow. Float.

3D Contour Bases are designed to make every run smoother and every turn more effortless by reducing the drag of the board tips. 3D Contour Bases enhance glide and improve float helping you ride faster and with better flow.

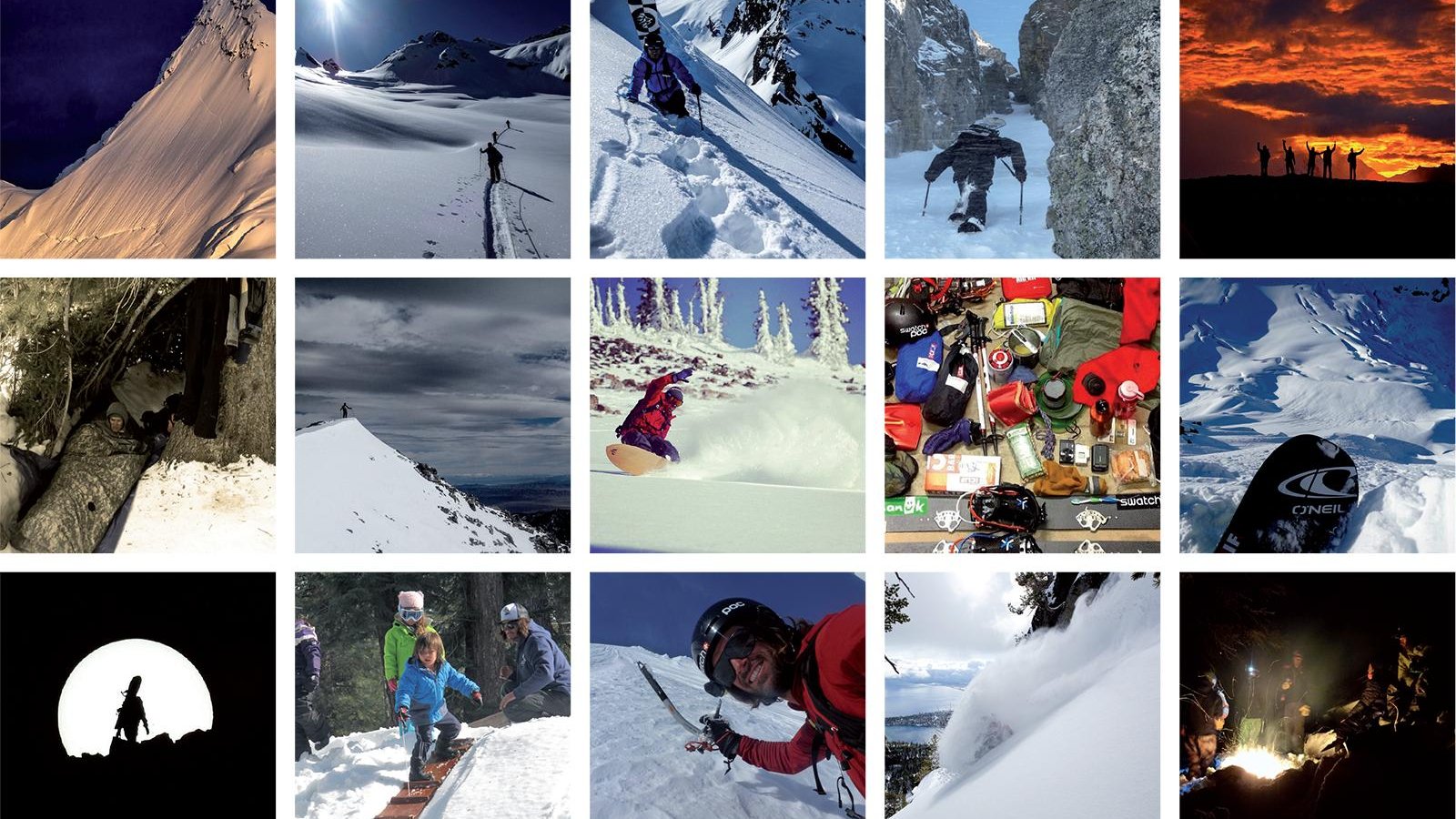

I’ve been on a quest to design a snowboard that offers the friction free glide and edge-to-edge fluidity of a surfboard for years. 3D Contour bases finally cracked the code on how to achieve this next level of board performance. Jeremy Jones

High Performance, Sustainably Made Gear

We design gear that balances performance, durability and sustainability. We strive to make equipment you can trust with the most eco-conscious materials possible. New for 2020, all our snowboards and splitboards are molded with Super Sap Bio-Resin.

Proud member of 1% For The Planet, we donate 1% of sales to fight climate change by supporting our non-profit partners Protect Our Winters and Community Carbon Trees.